-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Mar . 05, 2025 06:55

Back to list

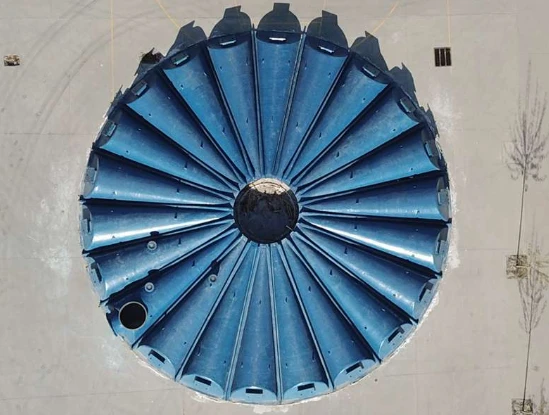

Transport Tanks

The use of FRP (Fiber Reinforced Polymer) in mining equipment is revolutionizing the industry, providing critical advancements in durability, efficiency, and safety. With a reputation for being highly resistant to corrosion, lightweight, and possessing remarkable strength, FRP materials are increasingly being integrated into mining operations, enhancing both equipment longevity and operational efficiency.

From an expertise standpoint, the shift to FRP mining equipment has garnered support from numerous industry experts. The polymer composites used in FRP manufacturing are engineered by specialists who tailor their properties to meet specific operational needs. This customization ensures a precisely controlled production process, yielding products that can take on the various challenges of mining environments. The specialized knowledge applied in the development of FRP mining equipment underscores both its credibility and its potential for transformative impact on mining processes. The adoption of FRP is also endorsed by authoritative industry studies and reports that highlight its effectiveness and operational benefits in the field. Institutions and experts have documented case studies where the deployment of FRP mining equipment has led to a marked improvement in operational efficiency and cost savings. These authoritative endorsements provide a strong foundation of trust and validation for the use of FRP in mining equipment, reinforcing its position as a preferred choice for modern mining applications. Trustworthiness in FRP mining equipment is further bolstered by the transparency and traceability within the manufacturing processes. Reputable manufacturers ensure that their FRP composites undergo rigorous testing to meet industry standards and certifications. This commitment to quality assurance guarantees consistent performance and reliability on the field, providing mining operations with the peace of mind that their equipment will withstand the test of time and conditions. In conclusion, the integration of FRP materials in mining equipment offers substantial benefits that cater to the modern demands of the mining industry. The superior properties of FRP—remarkable resistance to corrosion, lightweight composition, and safety features—work synergistically to enhance operational efficiency and safety. Supported by expertise, authoritative validation, and a commitment to trustworthy production standards, FRP mining equipment stands out as a revolutionary advancement poised to redefine mining operations for the future. As the industry continues to evolve, the adoption of FRP materials presents a forward-thinking solution that aligns with industry goals of sustainability, efficiency, and safety.

From an expertise standpoint, the shift to FRP mining equipment has garnered support from numerous industry experts. The polymer composites used in FRP manufacturing are engineered by specialists who tailor their properties to meet specific operational needs. This customization ensures a precisely controlled production process, yielding products that can take on the various challenges of mining environments. The specialized knowledge applied in the development of FRP mining equipment underscores both its credibility and its potential for transformative impact on mining processes. The adoption of FRP is also endorsed by authoritative industry studies and reports that highlight its effectiveness and operational benefits in the field. Institutions and experts have documented case studies where the deployment of FRP mining equipment has led to a marked improvement in operational efficiency and cost savings. These authoritative endorsements provide a strong foundation of trust and validation for the use of FRP in mining equipment, reinforcing its position as a preferred choice for modern mining applications. Trustworthiness in FRP mining equipment is further bolstered by the transparency and traceability within the manufacturing processes. Reputable manufacturers ensure that their FRP composites undergo rigorous testing to meet industry standards and certifications. This commitment to quality assurance guarantees consistent performance and reliability on the field, providing mining operations with the peace of mind that their equipment will withstand the test of time and conditions. In conclusion, the integration of FRP materials in mining equipment offers substantial benefits that cater to the modern demands of the mining industry. The superior properties of FRP—remarkable resistance to corrosion, lightweight composition, and safety features—work synergistically to enhance operational efficiency and safety. Supported by expertise, authoritative validation, and a commitment to trustworthy production standards, FRP mining equipment stands out as a revolutionary advancement poised to redefine mining operations for the future. As the industry continues to evolve, the adoption of FRP materials presents a forward-thinking solution that aligns with industry goals of sustainability, efficiency, and safety.

Next:

Related Products

Latest news

-

Fiberglass 90 Degree Elbow for Custom Tanks & High Pressure Pipes Durable and Corrosion ResistantNewsJun.24,2025

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025