2019 Good Quality Fiberglass Tank - Large Size Field Tanks – Jrain

2019 Good Quality Fiberglass Tank - Large Size Field Tanks – Jrain Detail:

The typical process for large size field tanks is:

1. Mobilize the manufacturing team and appoint Project Manager; Ship the machines and materials to project field.

2. Assembly the winding machine and mold at project field according to diameter of tank to be made.

3. Make liner and do winding work according to designed data.

4. Demoulding and then placing the tank to the right place.

5. Install the fittings such as nozzles, ladders, handrails, etc., and do hydrostatic test. Finally hand over to customer.

Jrain is equipped with highly customized winding machines and molds for field manufacturing of fiberglass tanks and vessels. The mechanical properties of the laminates obtained with the field winding equipment are identical to the properties of the laminates produced in workshop. Project schedule must include time to set-up mobile winding machines.

Different resins and fiberglass will be selected when designing the products for the storage and processing of corrosive or abrasive liquids and gases. Different agents and fillers can be used to meet different intended service conditions when required.

Field fabrication and installation can be highly cost-effective, and often overcome size and difficult access problems. On-site manufacturing can minimize transportation costs and can be effectively coordinated with other on-site contractors.

Jrain is rich experienced with manufacturing of large size FRP tanks and vessels at both Chinese and oversea project sites under different environments.

When hand over the machines to customer, Jrain can provide training about the machine usage if required.

Main standards we can follow:

• ASME RTP-1 • ASTM D3299 • ASTM D4097 • BS EN 13121

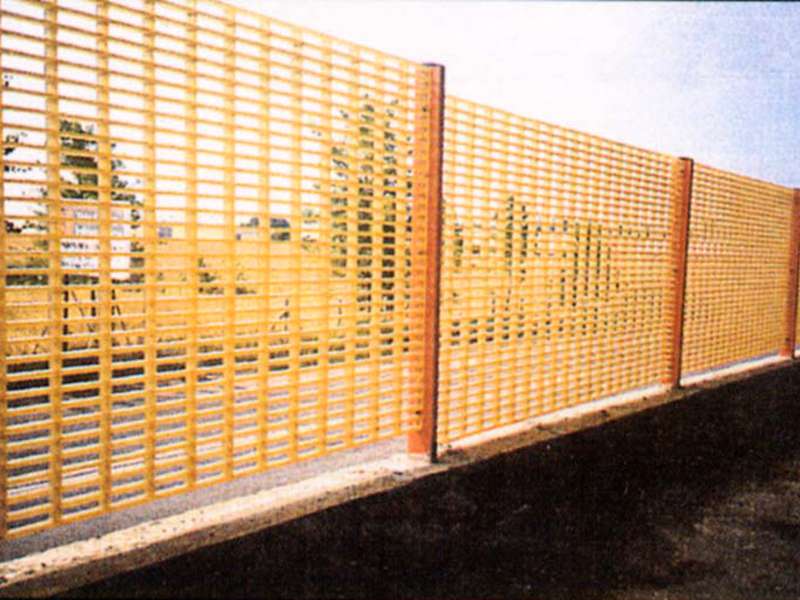

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and superb good quality control throughout all stages of manufacturing enables us to guarantee total buyer gratification for 2019 Good Quality Fiberglass Tank - Large Size Field Tanks – Jrain , The product will supply to all over the world, such as: Cambodia, Swansea, Orlando, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!