2019 Good Quality Molded Fiberglass Grating – Winding Machines for Pipes & Tanks – Jrain

2019 Good Quality Molded Fiberglass Grating – Winding Machines for Pipes & Tanks – Jrain Detail:

Complete production line of fiberglass (or fiberglass mortar) pipe:

| Diameter | 50mm – 200mm250mm – 2500mm2600mm – 4000mm |

| Length | 6m or 12m |

| Pressure | Max. 35 bar |

| Standard | AWWA C950, ASTM D3754, BS5480 |

| Control Program | Digital Servo |

| Control Mode | Automatic / Semi Automatic / Manual |

| Winding Angle | 15° to 90° |

| Filament feed speed | Max. 90m/min |

| Precision of lining up filament | 0.2mm |

| Joint Type | Bell and spigot, flange, taper, locking key, butt joint |

Pipe winders mainly include:

| Material feeding equipment | 1 set | Requisite |

| Liner application equipment | 1 set | Requisite |

| Winding machine | 1 set | Requisite |

| Curing machine | 4 sets | Requisite (quantity is optional) |

| Cutting & grinding machine | 1 set | Requisite |

| Extraction machine | 1 set | Requisite |

| Hydraulic pressure tester | 1 set | Optional |

| Mandrels for pipes | A lot | Quantity and specification are optional |

| Moulds for pipe fittings | A lot | Quantity and specification are optional |

Complete production line of fiberglass tank

| Diameter | 500mm – 4000mm4000mm – 12000mm12000mm – 20000mm |

| Length | 12m or less |

| Volume | Max. 5000m3 |

| Pressure | Max. 12 bar |

| Standard | ASTM 3299, ASME RTP-1, BS4994 |

| Control Program | Digital Servo |

| Control Mode | Automatic / Semi Automatic / Manual |

| Winding Angle | 15° to 90° |

| Filament feed speed | Max. 90m/min |

| Precision of lining up filament | 1mm |

| Tank Type | Vertical, Horizontal, Cone |

Filament winders are characterized by the high precision of winding line, high productivity, low energy-consumption, easy installation, adjustment and maintenance. They adopt the industrial computer control, so the usage and operation are very convenient.

Jrain is a professional manufacturer in fiberglass field for many years, therefore we know very well not only the machines and products, but also the materials selection, quality inspection, etc. We can provide all detailed information that you needed. Welcome to contact us for professional solutions.

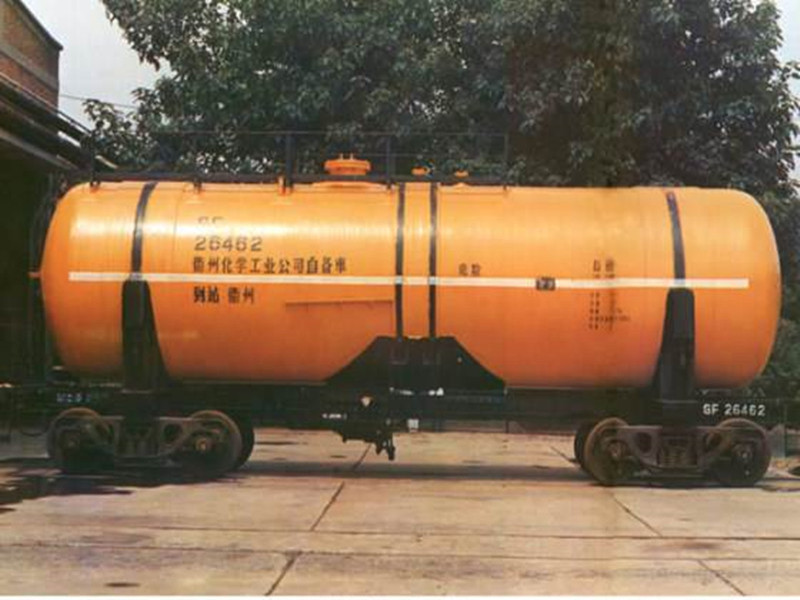

Product detail pictures:

Related Product Guide:

As for aggressive costs, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such high-quality at such rates we have been the lowest around for 2019 Good Quality Molded Fiberglass Grating – Winding Machines for Pipes & Tanks – Jrain , The product will supply to all over the world, such as: Russia, belarus, Holland, Providing Quality Products, Excellent Service, Competitive Prices and Prompt Delivery. Our products are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

Write your message here and send it to us