High Quality Fiberglass Scrubber - Scrubbers – Jrain

High Quality Fiberglass Scrubber - Scrubbers – Jrain Detail:

Fiberglass scrubbers are very popular for liquid storage, water treatment, FGD system, chemical processing and pollution control, the gas cleaning process, controlling gaseous emissions, especially polluted gases, waste incineration and power generation processes. Because:

In comparison to metal or rubber-lined steel products, Fiberglass reinforced plastic (FRP) have many advantages.

FRP is very light-weight, very strong and can be produced in a wide range of diameters, which has a direct impact in terms of extending the installation’s lifespan and cost saving.

In addition, FRP is a durable choice of materials compared to traditional materials, which means that FRP delivers significant benefits in terms of resistance to abrasion, chemical corrosion, rust, as well as to extremely low and extremely high temperatures. This makes it a long-lasting solution with low maintenance costs for clients.

The inside of fiberglass scrubbers are smooth, giving excellent flow characteristics and are easy to clean.

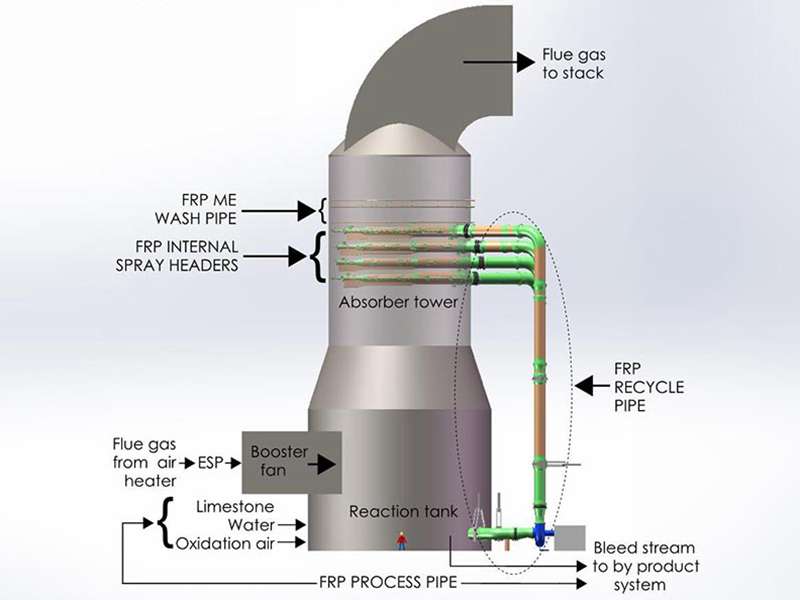

Supplemental system components including internal and external piping, spray banks, support beams, mist filters, packing, distribution systems and ducting can be fabricated in virtually any shape or configuration.

The exterior accessories such as ladders, platforms, railing, walkway, drainage, electrostatic discharge are also Jrain’s supply scope.

Jrain analyzes each new project and reviews the system performance specifications in order to select the right materials and construction methods, and finally designs and fabricates the fiberglass scrubbers based on requirements regarding medium, temperature, flow rate, pressure, earthquake, wind load and climate conditions.

When necessary, ECR glass fiber is used in addition to E-glass fiber in order to create higher chemical resistance, and a colored or semi-transparent top coat is used to resist UV light and provides protection.

As a full service supplier, Jrain designs, produces and installs equipment for the exterior of a scrubber such as ladder, platforms, drainage, protection liner and electrostatic discharge but also has the facility to serve you by delivering all internals such as spray banks, support beams, mist filters and packing.

Product detail pictures:

Related Product Guide:

we could supply good quality goods, aggressive cost and very best purchaser assistance. Our destination is "You come here with difficulty and we supply you with a smile to take away" for High Quality Fiberglass Scrubber - Scrubbers – Jrain , The product will supply to all over the world, such as: Jersey, Philippines, Hungary, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.