OEM/ODM Manufacturer Underground Fiberglass Tanks - Tanks and Vessels – Jrain

OEM/ODM Manufacturer Underground Fiberglass Tanks - Tanks and Vessels – Jrain Detail:

Typical tanks & vessels, including the supplemental components, can be fabricated in virtually any shape or configuration, demonstrating the flexibility inherent with FRP composites.

Using our proprietary technology, we have the ability to manufacture the tanks and vessels according to customer’s different requirements in our plant then transport them safely to your site.

For larger size tanks, we have the unique ability to build on-site to your exact specifications, and the maximum diameter can reach to 25m.

Our products are featured by:

• Highly resistant to a variety of chemicals, corrosive environments, and ultraviolet light

• High mechanical strength and a low weight

• Provide excellent thermal insulation with low heat loss when insulated

• Can be supplied with conductive liner made of carbon fiber and Sic abrasion-resistant liner

• Can be supplied in various fire categories and in various colors

• Excellent price-quality ratio and product output

Tank design features include:

• Full in-house CAD & FEA design and engineering capabilities for custom design

• Available with FDA approved or NSF-61 certified liners

• Available with abrasion-resistant liners

Types:

• Above ground and underground tanks in FRP

• Vertical flat bottom tanks

• Vertical dished bottoms tanks on FRP(or steel) legs

• Horizontal tanks on FRP(or steel, or without) saddles

• Tapered bottom silos (60° and 90°)

• Vertical tanks with integrated basin

• Vertical or horizontal agitating tank

Main standards we can follow:

• ASME RTP-1 • ASTM D3299 • ASTM D4097 • BS EN 13121

Raw materials and main processes:

• VE Resin, Iso Resin • C-veil, Synthetic veil, Carbon veil

• E-Glass, ECR Glass, mat, roving • MEKP or BPO/DMA cure systems

• Helically-wound, chop-hoop and hand lay-up construction

Tank design features include:

• Full in-house CAD & FEA design and engineering capabilities for custom design

• Available with FDA approved or NSF-61 certified liners

• Available with abrasion-resistant liners

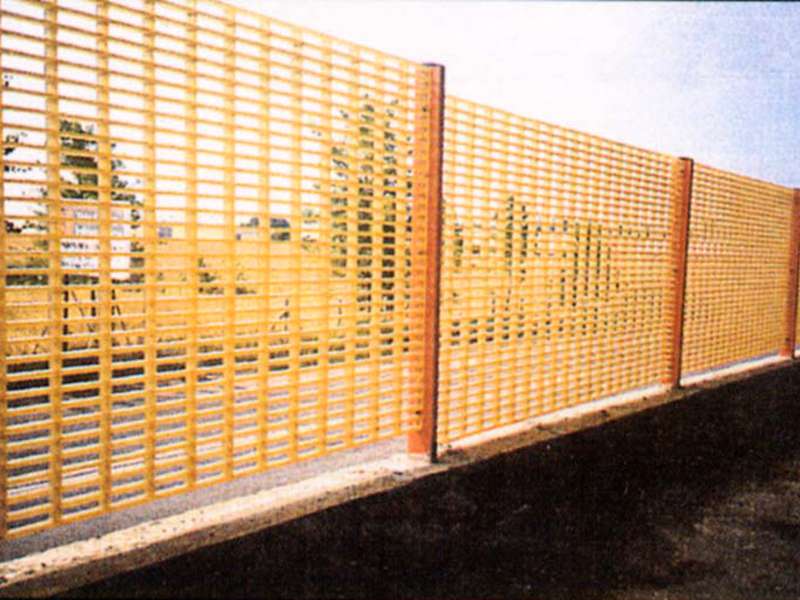

Product detail pictures:

Related Product Guide:

We can always satisfy our respected customers with our good quality, good price and good service due to we are more professional and more hard-working and do it in cost-effective way for OEM/ODM Manufacturer Underground Fiberglass Tanks - Tanks and Vessels – Jrain , The product will supply to all over the world, such as: Bulgaria, Hamburg, Angola, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and good service for domestic and international customers.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!