OEM/ODM Supplier Fiberglass Duct Corrosion Resistance - Piping System – Jrain

OEM/ODM Supplier Fiberglass Duct Corrosion Resistance - Piping System – Jrain Detail:

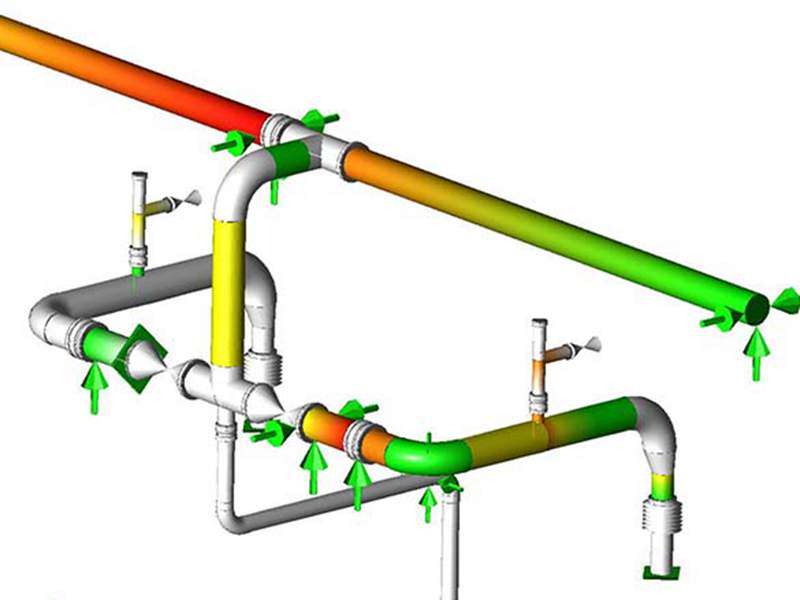

Fiberglass pipes include pure fiberglass pipes, sand pipes, insulation pipe, dual laminate pipe (with PVC, CPVC, PE, PP, PVDF, etc.) and so on

The wall construction of a fiberglass pipe system consists of three layers:

1. Liner: determines the optimal resistance to the medium.

2. Structural layer: provides high mechanical strength and resistance to loads.

3. Top coat: protects the piping system from weather, chemical penetration and UV radiation.

They are very popular in many industries because of the below advantages:

1. An ability to be tailored for a wide variety of corrosion resistant conditions

2. Light weight (less than 20% of steel, 10% of concrete)

3. Excellent strength to weight (stronger than steel on an equal weight basis)

4. Low coefficient of friction (>25% better than steel)

5. Good dimensional stability

6. Low thermal conductivity

7. Low long-term maintenance costs

Many different joint methods are available for fiberglass pipes such as butt joint, spigot and bell joint, flange joint, lock joint and others.

Typical process flow of fiberglass pipe includes:

1. Wind mylar, spray resin and wind surface mat;

2. Make liner and liner’s cure;

3. Add the mixing stuff or resin and mortar (depend on design) to increase stiffness;

4. Make the hoop and helix winding to meet the longitudinal and hoop requirements;

5. Cure the pipe with far infrared rays;

6. Cut and grind the pipe’s ends to make the bell and spigot joint (depend on joint method);

7. Extract the pipe from mandrel with hydraulic device;

8. Hydrostatic test for pipe. If qualified, release the pipe.

Jrain designs and offers fiberglass pipes to meet many national and international standards including DIN, ASTM, AWWA, ISO and many others. The standard length of one pipe is 6m or 12m. The customized length can be realized also by cutting.

Product detail pictures:

Related Product Guide:

"Quality initially, Honesty as base, Sincere company and mutual profit" is our idea, in order to create repeatedly and pursue the excellence for OEM/ODM Supplier Fiberglass Duct Corrosion Resistance - Piping System – Jrain , The product will supply to all over the world, such as: Germany, Japan, United Arab emirates, During in 11 years,We have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to provide the customer best products with lowest price. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We will always be your first choice. Trust us, you will never lose heart.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!