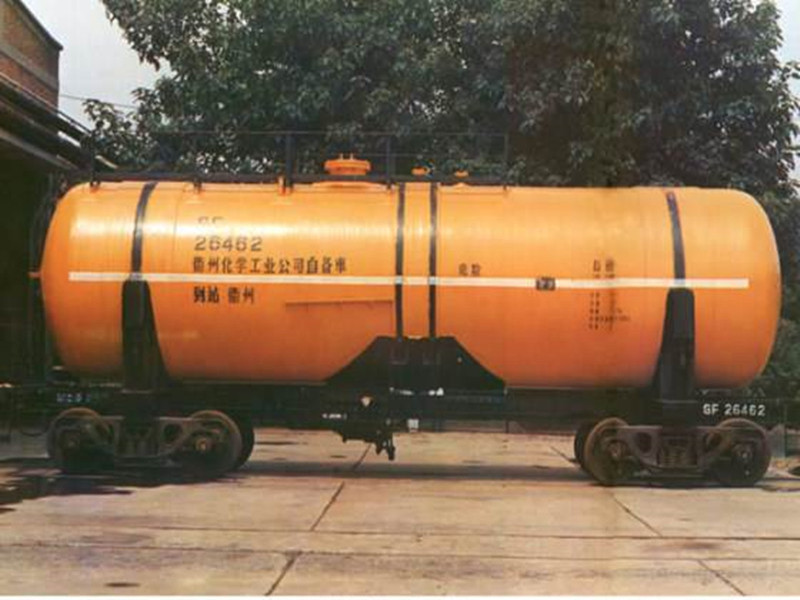

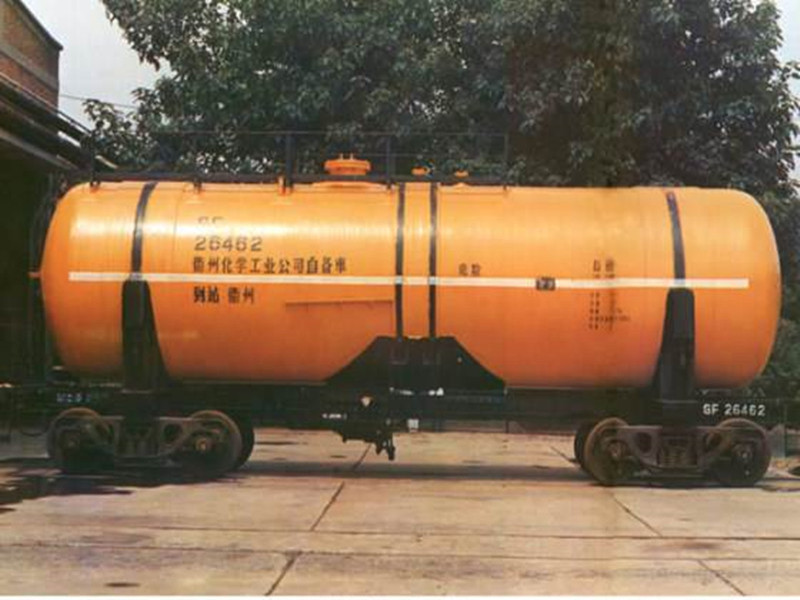

Transport Tanks

Fiberglass transport tanks are featured by:

● Microbiological corrosion resistance;

● Smooth surface and easy to be cleaned;

● High strength and high-pressure resistance;

● Aging resistance;

● Light weight;

● Low thermal conductivity;

● Effective constant temperature storage;

● Long service life, almost more than 35 years;

● Maintenance free;

● Heating or cooling devices can be added as per demanding.

Quality requirements with regard to the component of transportation tank are very high as hazardous materials are transported via public traffic routes. When necessary, dual laminate tanks can be designed and manufactured for special trailers (FRP with thermoplastic liner).

Fiberglass transport tanks are suitable for a lot of different mediums like below:

• Environmental protection: waste water, sewage and many other liquids and gases;

• Chemicals area: hydrochloric acid, sulfuric acid, nitric acid, hydrofluoric acid, phosphoric acid, sodium hydroxide, potassium hydroxide, calcium hydroxide, ammonium hydroxide, hydrogen peroxide, etc.

• Living area: brine / salt water, pure water, ultrapure water

Fiberglass transport tanks are very popular in many industries such as pharmacy, national defense, petroleum and chemical, environmental protection, smelting, food and so on.

Jrain produce our own moulds, thereby ensuring that there are virtually no limits in terms of size and diameter of the tanks.

Jrain’s scheduling ensures that we complete industrial projects in record time without compromising the quality and safety of our products. Incoming raw materials are subject to stringent entry checks, our stock is continuously monitored, working hours are constantly timed and costs always calculated. Potential obstacles in the systems can therefore be detected quickly and are solved immediately.